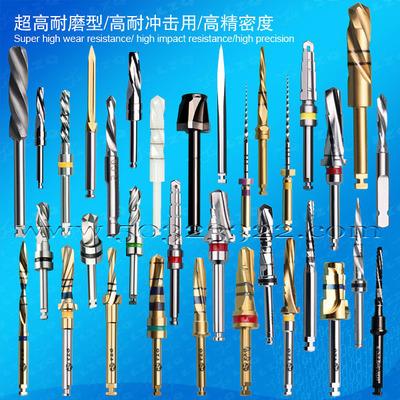

The dental practice is incomplete without the essential tool that is the diamond burr. These are employed in a variety of tasks, ranging from contouring and polishing tooth enamel to eradicating tooth decay and getting a tooth ready for dental restoration. What’s more, the burs are also utilized in removing excess material from pearly whites, as seen during applications involving crowns and bridges. Every type of dental diamond burr has been crafted for a distinct purpose, and this article will explore their various forms and functionalities.

Enamel shaping and smoothening as well as the removal of decay are just some of the tasks that can easily be carried out with the help of round burs – the most frequently seen type of dental diamond burs. In addition, a tooth may be prepped up for a dental restoration utilizing the same round-edged instruments.

Tapered burs – tooth-shaping tools with a tapered form- are often employed for a variety of dental purposes, such as contouring enamel, eliminating decay, and setting up a toothfor a dental restoration. As the enamel found round the sides of a tooth is thicker, this type of bur is most usuallyapplied in these areas.

Burs with an inverted cone-shaped tip, known as inverted cone burs, are used to shape and even out the enamel surface of teeth, eliminating decay as needed prior to applying a dental restoration. Ideal for regions featuring thinner enamel, such as the edges of a tooth, inverted cone burs get the job done quickly and efficiently.

When it comes to a dental diamond burs, the flat type stands out. It consists of a flat head that is used to mold and refine the hard enamel that lines teeth, clear away cavity debris, and make preparations for a dental restoration. Mostly, these flat burs are applied to regions with thick enamel coverage like near the edges of a tooth.

The selection of a dental diamond bur relies heavily on the type which best facilitates the required procedure; curved blades for shaping and smoothing the enamel, inverted cones for eliminating decay, and flatter configurations for the making ready of a tooth intended for restoration.

Depending on the procedure, bur sizes will vary; finer specimens are preferred when shaping and buffing enamel whilst a more sizable one may be required for decay removal. Different types of burs exist, making tailoring the right bur to a task an integral part of the process.

Dental diamond burs are existing in a wide selection for the array of procedures they are employed in at dentistry offices. From contouring and polishing enamel to removing decay and readying teeth for dental restoration, the different types and sizes of burs are shaped to serve their purpose perfectly. Therefore, when deciding on a dental diamond bur for your project, it is essential to choose an appropriate style and size to best suit your needs.

Dentists make regular use of diamond burs, which provide a strong, effective method for modifying the enamel of teeth; this is necessary to allow for fillings, veneers, crowns, and other restorations. At its core, the bur is a metal shank that is covered in a sharpened coating of diamond particles. This coating is carefully bonded to the underlying alloy with expert precision, granting a durable and reliable abrasive surface for shaping and polishing teeth.

An array of diamond burs for dental procedures exist, with round burs being the most iconic. They enable tooth enamel to be precisely cut and shaped by their wheel-like design, endlessly rotating over the surface in a circular fashion. Round burs come in various sizes from minuscule to substantial, serving a variety of purposes accordingly.

If you’re looking for precise cutting and shaping capabilities, you want to check out tapered burs. These specialized dental burs have been carefully crafted with a tapered shape, allowing for an enhanced level of accuracy when working with tooth enamel. Need to switch sizes during the procedure? No problem; these burs are available in a range of sizes from tiny to huge, suited for any job.

From round and tapered burs to conical ones, there is a wide range of burs created with the purpose of cutting and forming tooth enamel into a conical shape. Cone-shaped tools can be used to cut and shape hidden areas of the tooth, thanks to their varied sizes; from small to large, they enable practitioners to access and treat all kinds of spots.

Dentists have a variety of burs that come in assorted shapes and sizes, all designed to assist in cutting and shaping tooth enamel. Pointed burs are no exception, as they are precisely meant to cut even the most intricate of patterns into the tooth. Tiny to hefty, each pointed bur is used to craft grooves and other tough-to-reach spots on the teeth.

At long last we arrive at the diamond-tipped burs. Intended for the cutting and forming of tooth enamel, such burs boast an impressively sharp diamond-tipped edge. Most useful for attending to the more petite and tricky spots of the tooth, these burs come in a variety of sizes from mini to huge which can respectively handle a wide range of tasks.

Serving as a fundamental dentistry implement, dental diamond burs play an important role in the preparation of tooth enamel for fillings, crowns, veneers and other restorations. Adaptable in size and shape to suit all requirements of cutting, sculpting or smoothing projects, dentists must be able to select the precisely appropriate dental bur for a procedure to produce excellent outcomes.

Related Product

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Post time: 2023-07-30