When it comes to dental drills, the size of the bit is of utmost importance in the success of the entire operation. Looking at all the drill bit sizes available on the market, it can be confusing to select one that best suits your purpose. Herein, we will take a more in-depth look into determining the best drill bit size and what points should be taken into account while making your choice.

When choosing the appropriately-sized drill bit for a job, there are several things to take into consideration. Firstly, the type of material you’re penetrating. Harder materials such as metal or ceramic require a larger bit than materials like wood or plastic which are less firm. Moreover, the desired size of the hole will also influence the bit size requisite; for a shallow opening you’ll need a narrower bit and if a deeper hole is desired, you’ll have to use a fatter bit.

When selecting the size of your bit, the next consideration is its type. HSS (high-speed steel) and carbide drill bits are the two primary types available, the former typically chosen by those looking for value and a general-purpose tool. For materials like ceramic or metal, however, carbide drills offer unparalleled performance at a higher price point.

When selecting a bit for your dental drill, it is essential that you pay attention to the size of its shank. The shank is the part which inserts into the drill’s chuck and must be the right size so it connects with the drill securely. In most cases, this will be 3/32”, but some drills may require a larger variant.

When it comes to the range of drill bit sizes, the common options are 1/8”, 3/32” and 1/4” – usually reserved for everyday use on soft materials like wood and plastic. However, when you need to break through hard objects such as metal or ceramic, you’ll likely want to select a larger variant – perhaps 3/16” or a hefty 1/2”.

Ultimately, selecting the right type of drill bit tip is essential. Options range from flat to pointed or even spiral; ultimately, the shape you choose pertains to both the material of what you’re drilling into as well as the size of the hole you’re making. Soft materials usually are best met with flat tips, while a pointed or spiral tip will prove more suitable when it comes to harder material.

Making a wise choice in drill bit size can be daunting – yet essential – for the success of your project. To calculate the ideal size, pay attention to the material you are boring through, as well as the diameter of the hole and the kind of tip that would be ideal for your requirements. Doing this will set you up for success while allowing you to complete the task fast and with remarkable outcomes.

Dental drills are a crucial part of any dentist’s toolkit, utilized for a multitude of utilitarian tasks. From eradicating decay, to refining the surface of teeth for crowns and bridges, the dental drill is a vital asset when it comes to readying a mouth for treatment. However, with so many variations in drill bit sizes, it is important to know which is best suited for each job.

To create the perfect smile, a dental drill bit is essential. Composed of stainless steel or cobalt-chromium alloy, these miniature, rotating tools are precisely placed to remove decay, manoeuver enamel into the desired shape and succesfully fill teeth, plus ensure the surfaces are ready for crownains and bridges. While these drill bits come in various sizes and styles, two parameters determine their size – the diameter which defines the scope of the hole that can be constructed, and the length which affects the intended depth.

When performing dental procedures, one needs to be aware of drill bit sizes. The biggest is the 1/8 inch drill bit which is used for large cavity preparation, root canal therapy, and crown preparation. A step down, the 3/32 inch drill bit is ideal for prepping big cavities as well as for crown preparation. The 1/16 inch bit is ideal for medium-sized cavities and to create and fill teeth. For small cavities and contour filling in teeth, a 3/64 inch drill bit does the trick. And finally, the 1/32 inch drill bit – the littlest of them all – is suitable for very minute cavities and detailing.

Choosing the appropriate dental drill bit for a particular procedure calls for some careful consideration. Both the size of the tooth and the depth of the cavity should be considered in order to determine the right choice. In practice, if you are dealing with a large cavity, or a large tooth, you will need to go for the drill bit of 1/8 inch; yet, if the cavity – or tooth – is small, then a drill bit of 1/32 inch would provide the necessary precision.

From size to speed, there are a number of elements to consider when picking the perfect drill bit for the job. Not only must its dimensions meet the requirements of the project, but one must also factor in the type of material being drilled as well as the technique being employed. Keep in mind that various bits are specifically made for certain materials and techniques; thus, you must select one that’s appropriate for both of these considerations. Moreover, the operating speed of the drill should be considered so one can ensure they get the best yield.

Choosing the correct dental drill bit for a procedure is of paramount importance. Factors such as the size, material, and speed of the drill must be assessed and weighed against the type of procedure being undertaken. As drill bits come in a variety of designs and sizes, ensuring that the right one is picked for the job should be top priority. Similarly, speed can also affect results—adjusting it to the appropriate level will ensure precise and accurate work. Deciding on these criteria beforehand will provide maximum benefit for each dental procedure.

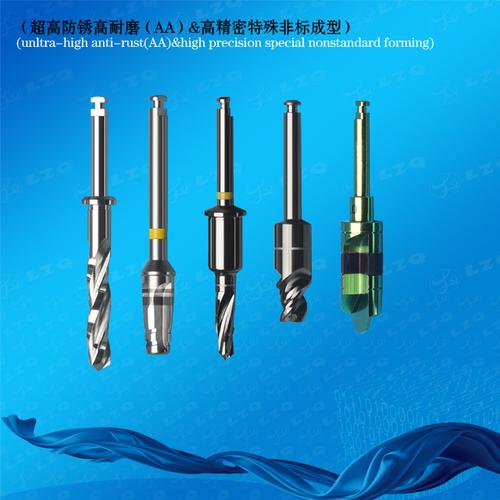

Related Product

HP Deburring Carbide Burs

Product Information Brand MSK Material Tungsten Steel Model Grinding Head Custom Processing Yes Feature: The dental grinding head is made of tungsten steel with stabl […]

Carbide Roland CAD/CAM Burs

Product Information Origin Tianjing, China Brand MSK Number Of Blades 4 Product Name Dental Special 4-Blade End Mill Model D Number Of Blades Z X N L d 4TD2060HB 2 4 […]

Diamond Bur Ball Round

Product Information Product Name Dental 4-Flute Ball End Mill Brand MSK Model D Number Of BladesZ X N L d 4BTD2060 2 4 6 6 50 3 4BTD2010 2 4 6 10 50 3 4BTD2016 2 4 6 […]

Step Bur Milling Bur Grinder for Glass Cerami

Product Information Origin Tianjing, China Shank Diameter 1.8 (mm) Brand MSK Scope Of Application CEREC3 Grinding Equipment Material Stainless Steel/Carbide Main Sales Areas […]

Supply Roland DLC Zirconia Burs

Product Information Origin Tianjing, China Series Dental Bur Brand MSK Cutting Edge Form 2 Blade/3 Blade Ball Diameter (Mm) 0.6, 1, 2 Material Very Fine Grained Cemented Car […]

Diamond Coating Round Diamond Cutters

Product Information Origin Tianjing, China Series U Series Brand MSK Cutting Edge Form Helical Structure Ball Diameter (Mm) 3 Material Carbide Minimum Cutting Diameter At Th […]

Dental CAD/CAM Milling Burs

Product Information Origin Tianjing, China Material Stainless Steel Brand MSK Applicable Machine Tools A Variety Of Options Custom Processing Yes Whether To Coat No Is It a […]

Post time: 2023-08-02